Medical cannabis testing abides by strict standards in Australia. Medicines derived from cannabis are considered pharmaceutical-grade if produced in accordance with Good Manufacturing Practices (GMP), and testing helps ensure they are consistent, of a high quality level and free from contaminants and pesticides. Many sophisticated pieces of equipment are used to test medical cannabis products accurately. Testing is one of the key reasons that medical cannabis is safer to use than recreational / illicit cannabis.

What cannabis regulations currently exist in Australia?

The main cannabis regulations in Australia come from the Therapeutic Goods Administration (TGA) and the Office of Drug Control (ODC). While the ODC is more concerned with licensing and regulation of cannabis production, the TGA is more focused on the final medicines themselves. Two of the most important testing standards for medical cannabis are the TGO 93 and 100.

TGO 93

The TGO 93 provides a minimum quality standard that all medical cannabis products must meet to be sold in Australia. This includes products which are imported and products which are produced locally. The supplier must provide information about all of the cannabis and non-cannabis products that are being incorporated into the product. The product must be within a certain amount of how much is listed to be allowed to market.

The TGO 93 also deals with potential contaminants in the product. Part of the quality standard is ensuring that substances such as pesticides and heavy metals are kept below the appropriate threshold.

TGO 100

The TGO 100 is specifically concerned with limiting the amount of harmful microbes in medical cannabis products. Included in this are both fungi such as mould and harmful bacteria such as e.coli.

What testing does medical cannabis go through?

Medical cannabis goes through testing for both contents and contaminants. Testing the contents helps to ensure each batch contains the appropriate compounds. This is particularly important when dealing with tetrahydrocannabinol (THC content) in medical cannabis products. Products must be consistent between different batches so that users can apply the product as intended. Testing for contaminants ensures that unwanted substances have not made their way into the products. Bacteria and microbes are common issues, which are often traced back to the growing process. The levels of fungi, yeast and certain bacteria must be below a certain amount or the products can not be sold.

What kind of equipment is used in medical cannabis testing laboratories?

A range of precision equipment and analytical instruments are used in medical cannabis testing laboratories. Through various forms of testing, the exact composition and potency of a medical cannabis product can be determined. This ensures a medical cannabis product has the correct concentrations of the relevant chemicals and is free of harmful contaminants. The types of instruments and analytical methods used to this effect are determined by the relevant Pharmacopeia Standards. These are set out by the Therapeutic Goods Administration (TGA) in Australia

Analytical chromatography machines

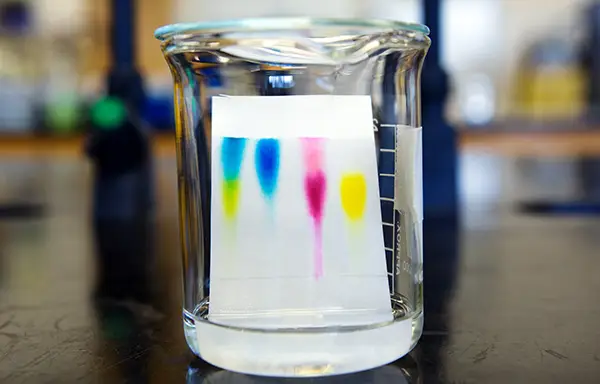

An analytical chromatography machine is a device used to measure the phytocompound content of a medical cannabis sample. It does this by dissolving a sample into a solvent and pushing it through an absorbent surface. Different compounds move through the absorbent surface in their own time and while leaving distinct colour trails. This allows them to be identified while the separation between colours determines their concentration. Gas chromatography, liquid chromatography and high-performance liquid chromatography (HPLC) are used depending on the testing requirements, but HPLC is typically the most reliable method.

High performance liquid chromatography measures a range of different cannabis compounds ranging from terpenes to cannabinoids like tetrahydrocannabinol (THC). The process begins by drying and finely grinding the relevant compounds. Then the sample is added to a solvent, typically made from a mixture of ultra-high purity methanol, ethanol and water. This increases the particulate surface area, which improves extraction efficiency for all target compounds. The solvent used has a high affinity for the target compounds and can extract 99.99% of them.

The HPLC works by using the difference in molecular polarity of the target compounds to separate the individual components. A small sample is taken from the extracted solution and a solvent is pumped through it. The solvent moves the sample through a thin tube (column) filled with a special material with a particular polarity. Because of this, some target compounds are attracted to the material more than others. As a result of this attraction, the time it takes for them to exit varies.

The solvent then moves the separated components to a detector. This creates a chromatogram – a chart of time and intensity. Individual compounds are detected at particular times based on the solvent and the tube chosen. The identity of each compound is determined based on the time they took to exit. The quantity or concentration of the compound is determined by the magnitude of the detection. Before testing, 100% pure samples of each target compound are used to determine the appropriate exit times.

Mass spectrometers

A mass spectrometer (MS) is used to measure the mass of molecules within a sample. It’s a useful way to determine the amount of cannabinoids, terpene, mycotoxins and pesticide residue remaining in the sample. Mass spectrometry is often used with gas chromatography as a separation technique. The overall method is similar to that of the HPLC. However, an inert gas is used to atomise the sample and send it through a column rather than the solvent method. As the separated sample exits the tube, MS detectors fire electrons into it. This breaks the compounds into fragments, which each have their own time and pattern for exiting the tube. The MS can measure the mass of the fragments and match it up with the exit time to determine the compound.

Moisture analysers

Moisture analysers determine the exact moisture content of a sample. This is important because the composition of a cannabis sample is given as dry weight (the mass of a compound if all water was removed). It also extends to cannabis potency, which is reported as a percentage of the dry weight. The reason for this is that the amount of water a sample holds can skew the readings for compounds such as THC, making them inconsistent. Moisture is eliminated from a sample by placing it into a drying oven until the mass no longer changes. When the mass plateaus, this indicates that all water has been evaporated from the sample. This weight is used to calculate the dry weight basis concentrations of all compounds measured in the sample.

How does medical cannabis differ from recreational cannabis?

The primary differences between medical cannabis and recreational cannabis are the standards applied to each. Medical cannabis products are regulated and tested. This means you know they’re free from contaminants and you know exactly what they contain. Recreational cannabis is a black market product and offers no such guarantee. It could contain harmful amounts of certain compounds or be laced with foreign substances which could be very damaging, particularly if being inhaled. Check our page on the differences between recreational and medical cannabis for more information.

Little Green Pharma adheres to the strict standards within the Australian medical cannabis industry and is proud to be a local grower and manufacturer. We have been a leader in the Australian medical cannabis industry for a number of years. If you would like to learn more about accessing medical cannabis, browse our educational articles or contact us today.

Have questions?

Our friendly team is available to assist you with any queries.